官方易記域名:

新澳門免費精準(zhǔn)龍門客棧,澳門一碼一肖一待一中四不像一,澳門最精準(zhǔn)免費資料大全旅游團(tuán),澳門慈善精準(zhǔn)資料大全,新奧精準(zhǔn)免費提供網(wǎng)址,新澳門內(nèi)部精準(zhǔn)公開,2025全年免費資料大全,新澳精準(zhǔn)資料,最準(zhǔn)一肖100%中一獎,新澳門最精準(zhǔn)確精準(zhǔn)龍門,2025澳門精準(zhǔn)正版免費大全簡介,2025年新澳天天開好彩資料,2025澳門精準(zhǔn)正版免費,新奧門免費資料大全在線查看,2025新澳門精準(zhǔn)免費大全數(shù)據(jù)解答,管家婆期期準(zhǔn)四肖四碼,新奧最精準(zhǔn)免費提供,新奧精準(zhǔn)免費提供港澳彩,澳門慈善資料免費大全,7777788888精準(zhǔn)一肖中特,管家婆100中獎,2025年正版資料免費大全,澳門最精準(zhǔn)正最精準(zhǔn)龍門蠶,2025全年資料免費,2025精準(zhǔn)資料免費解答,2025澳門正版免費精準(zhǔn)大全,2024正版資料免費大全,新澳門最精準(zhǔn)正最精準(zhǔn)查詢,新奧天天開獎資料大全的推薦,澳門最準(zhǔn)資料大全免費,2025新澳今晚開獎結(jié)果,2025新澳門精準(zhǔn)免費大全,100%最準(zhǔn)的一肖,澳門正版免費大全精準(zhǔn),2025年天天開彩免費資料,7777788888新版跑狗 圖,7777788888王中王開獎十記錄網(wǎng)一,2025精準(zhǔn)免費資料查詢,新澳門精準(zhǔn)正版免費,澳門一碼一肖一待一中四,2025新澳門特馬今晚開獎掛牌,新澳門王中王100期期中,澳門天天開彩期期精準(zhǔn),澳門六和資料查詢2025,2025年澳門正版大全,新澳門管家婆100%期期中,2025今晚必中必開一肖,澳門新奧9點35,新澳天天開獎資料大全最新版,新澳今天晚上9點30分

港彩高手出版精料

澳門精華區(qū)

香港精華區(qū)

- 182期:【貼身侍從】必中雙波 已公開

- 182期:【過路友人】一碼中特 已公開

- 182期:【熬出頭兒】絕殺兩肖 已公開

- 182期:【匆匆一見】穩(wěn)殺5碼 已公開

- 182期:【風(fēng)塵滿身】絕殺①尾 已公開

- 182期:【秋冬冗長】禁二合數(shù) 已公開

- 182期:【三分酒意】絕殺一頭 已公開

- 182期:【最愛自己】必出24碼 已公開

- 182期:【貓三狗四】絕殺一段 已公開

- 182期:【白衫學(xué)長】絕殺一肖 已公開

- 182期:【滿目河山】雙波中 已公開

- 182期:【寥若星辰】特碼3行 已公開

- 182期:【凡間來客】七尾中特 已公開

- 182期:【川島出逃】雙波中特 已公開

- 182期:【初心依舊】絕殺四肖 已公開

- 182期:【真知灼見】7肖中特 已公開

- 182期:【四虎歸山】特碼單雙 已公開

- 182期:【夜晚歸客】八肖選 已公開

- 182期:【夏日奇遇】穩(wěn)殺二尾 已公開

- 182期:【感慨人生】平特一肖 已公開

- 182期:【回憶往事】男女中特 已公開

- 182期:【瘋狂一夜】單雙中特 已公開

- 182期:【道士出山】絕殺二肖 已公開

- 182期:【相逢一笑】六肖中特 已公開

- 182期:【兩只老虎】絕殺半波 已公開

- 182期:【無地自容】絕殺三肖 已公開

- 182期:【涼亭相遇】六肖中 已公開

- 182期:【我本閑涼】穩(wěn)殺12碼 已公開

- 182期:【興趣部落】必中波色 已公開

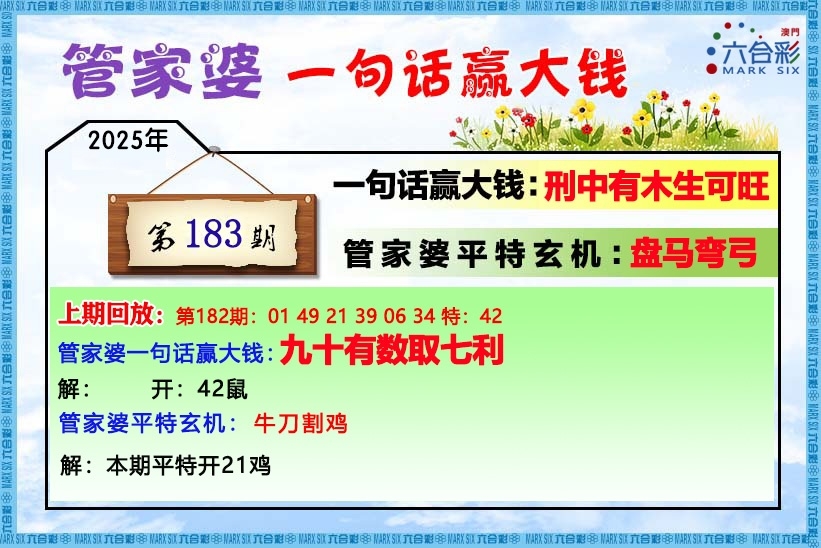

【管家婆一句話】

【六肖十八碼】

天天好彩【六肖中特】

天天好彩【平尾心水秘籍】

天天好彩【幽默猜測】

天天好彩澳門正版圖庫

- 澳門四不像

- 澳門傳真圖

- 澳門跑馬圖

- 新掛牌彩圖

- 另版跑狗圖

- 老版跑狗圖

- 澳門玄機(jī)圖

- 玄機(jī)妙語圖

- 六麒麟透碼

- 平特一肖圖

- 一字解特碼

- 新特碼詩句

- 四不像玄機(jī)

- 小黃人幽默

- 新生活幽默

- 30碼中特圖

- 澳門抓碼王

- 澳門天線寶

- 澳門一樣發(fā)

- 曾道人暗語

- 魚躍龍門報

- 無敵豬哥報

- 特碼快遞報

- 一句真言圖

- 新圖庫禁肖

- 三怪禁肖圖

- 正版通天報

- 三八婆密報

- 博彩平特報

- 七肖中特報

- 神童透碼報

- 內(nèi)幕特肖B

- 內(nèi)幕特肖A

- 內(nèi)部傳真報

- 澳門牛頭報

- 千手觀音圖

- 夢兒數(shù)碼報

- 六合家寶B

- 合家中寶A

- 六合簡報圖

- 六合英雄報

- 澳話中有意

- 彩霸王六肖

- 馬會火燒圖

- 狼女俠客圖

- 鳳姐30碼圖

- 勁爆龍虎榜

- 管家婆密傳

- 澳門大陸仔

- 傳真八點料

- 波肖尾門報

- 紅姐內(nèi)幕圖

- 白小姐會員

- 白小姐密報

- 澳門大陸報

- 波肖一波中

- 莊家吃碼圖

- 發(fā)財波局報

- 36碼中特圖

- 澳門男人味

- 澳門蛇蛋圖

- 白小姐救世

- 周公玄機(jī)報

- 值日生肖圖

- 鳳凰卜封圖

- 騰算策略報

- 看圖抓碼圖

- 神奇八卦圖

- 新趣味幽默

- 澳門老人報

- 澳門女財神

- 澳門青龍報

- 財神玄機(jī)報

- 內(nèi)幕傳真圖

- 每日閑情圖

- 澳門女人味

- 澳門簽牌圖

- 澳六合頭條

- 澳門碼頭詩

- 澳門兩肖特

- 澳門猛虎報

- 金錢豹功夫

- 看圖解特碼

- 今日閑情1

- 開心果先鋒

- 今日閑情2

- 濟(jì)公有真言

- 四組三連肖

- 金多寶傳真

- 皇道吉日圖

- 澳幽默猜測

- 澳門紅虎圖

- 澳門七星圖

- 功夫早茶圖

- 鬼谷子爆肖

- 觀音彩碼報

- 澳門不夜城

- 掛牌平特報

- 新管家婆圖

- 鳳凰天機(jī)圖

- 賭王心水圖

- 佛祖禁肖圖

- 財神報料圖

- 二尾四碼圖

- 東成西就圖

- 12碼中特圖

- 單雙中特圖

- 八仙指路圖

- 八仙過海圖

- 正版射牌圖

- 澳門孩童報

- 通天報解碼

- 澳門熊出沒

- 鐵板神算圖

澳門天天好彩免費資料大全

- 殺料專區(qū)

- 獨家資料

- 獨家九肖

- 高手九肖

- 澳門六肖

- 澳門三肖

- 云楚官人

- 富奇秦準(zhǔn)

- 竹影梅花

- 西門慶料

- 皇帝猛料

- 旺角傳真

- 福星金牌

- 官方獨家

- 貴賓準(zhǔn)料

- 旺角好料

- 發(fā)財精料

- 創(chuàng)富好料

- 水果高手

- 澳門中彩

- 澳門來料

- 王中王料

- 六合財神

- 六合皇料

- 葡京賭俠

- 大刀皇料

- 四柱預(yù)測

- 東方心經(jīng)

- 特碼玄機(jī)

- 小龍人料

- 水果奶奶

- 澳門高手

- 心水資料

- 寶寶高手

- 18點來料

- 澳門好彩

- 劉伯溫料

- 官方供料

- 天下精英

- 金明世家

- 澳門官方

- 彩券公司

- 鳳凰馬經(jīng)

- 各壇精料

- 特區(qū)天順

- 博發(fā)世家

- 高手殺料

- 藍(lán)月亮料

- 十虎權(quán)威

- 彩壇至尊

- 傳真內(nèi)幕

- 任我發(fā)料

- 澳門賭圣

- 鎮(zhèn)壇之寶

- 精料賭圣

- 彩票心水

- 曾氏集團(tuán)

- 白姐信息

- 曾女士料

- 滿堂紅網(wǎng)

- 彩票贏家

- 澳門原創(chuàng)

- 黃大仙料

- 原創(chuàng)猛料

- 各壇高手

- 高手猛料

- 外站精料

- 平肖平碼

- 澳門彩票

- 馬會絕殺

- 金多寶網(wǎng)

- 鬼谷子網(wǎng)

- 管家婆網(wǎng)

- 曾道原創(chuàng)

- 白姐最準(zhǔn)

- 賽馬會料